For manufacturers seeking efficiency, the adoption of automated technology is no longer optional. The as/rs automated storage and retrieval system provides a structured approach to storing and moving materials with greater accuracy. PassionIOT has positioned its solutions to support enterprises that handle sensitive and high-value components, ensuring that inventory is managed in a controlled and transparent way.

Optimizing Processes Across Industries

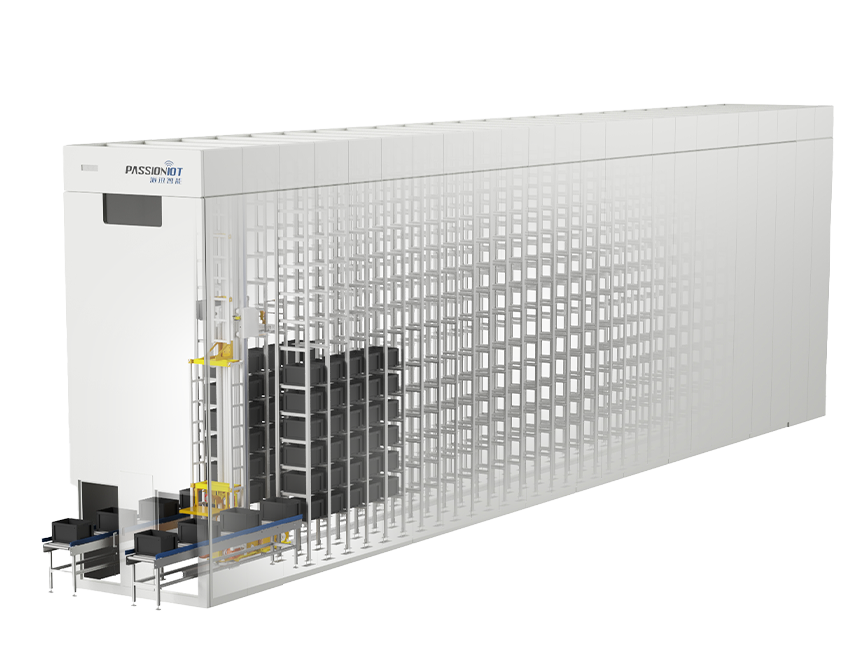

An as/rs storage system is designed to simplify the movement of goods while maximizing warehouse capacity. Businesses that once relied on manual processes often faced errors, misplaced materials, and inefficiencies. By applying PassionIOT technologies such as the Smart Vertical Carousel and Smart Vertical Lift Module, organizations benefit from automated retrieval and storage tailored to their operational needs. This not only saves time but also reduces the risks associated with human handling, particularly in sectors where precision is critical.

Bridging Automation with Digital Management

Incorporating an as/rs automated storage and retrieval system goes beyond physical hardware; it also requires integration with digital tools. PassionIOT provides intelligent platforms that connect equipment with data management systems, enabling companies to track material flow in real time. Whether in semiconductor production, electronics manufacturing, or other industrial fields, this combination of hardware and software enhances visibility and supports a continuous production cycle without delays.

Conclusion

Enterprises aiming to upgrade warehouse operations benefit significantly from implementing an as/rs storage system. PassionIOT continues to design scalable solutions that balance automation, digital oversight, and operational flexibility. By focusing on practical industrial applications, they enable businesses to maintain stable workflows and achieve long-term improvements in storage and logistics efficiency.