The furniture manufacturing industry demands high precision and efficiency in its production processes. With the increasing need for customization and faster turnaround times, manufacturers are seeking solutions that can streamline operations. HUAHUA CNC provides advanced technologies to optimize furniture production lines, enhancing both productivity and product quality. This article explores how HUAHUA CNC’s solutions for furniture production lines can significantly reduce labor costs while improving overall efficiency.

Enhanced Precision with CNC Furniture Machines

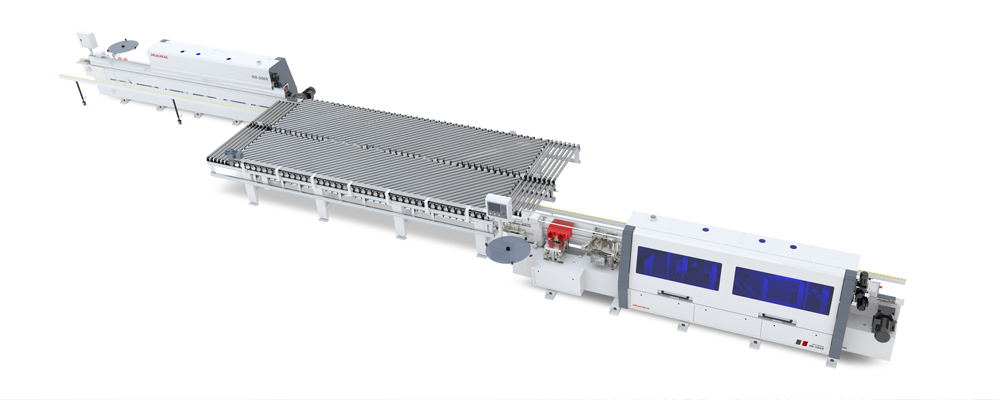

CNC technology has revolutionized the way furniture is made. HUAHUA CNC’s CNC furniture machines offer precise cutting, drilling, and edge banding, ensuring that every piece of furniture meets the exact specifications. The automation process reduces human error and enhances the quality of the final product. By integrating CNC furniture machines into a production line, manufacturers can achieve higher consistency and better finished products.

Streamlining Production with Custom Furniture Production Lines

With HUAHUA CNC, manufacturers can optimize their furniture production line by incorporating a range of automated systems. These systems are designed to work seamlessly together, from CNC nesting machines to edge banding and drilling stations. The result is a more efficient workflow that minimizes downtime and maximizes output. Furthermore, the line’s ability to handle multiple workpiece shapes enhances flexibility, allowing manufacturers to meet diverse customer needs with ease.

Reduced Labor Costs and Improved Productivity

The integration of HUAHUA CNC’s advanced machinery into the furniture production line significantly reduces the need for manual labor. The automation of processes such as cutting, drilling, and sorting results in less reliance on workers, which leads to a reduction in labor costs by up to 60%. This shift allows companies to allocate resources more efficiently and boost overall productivity.

Conclusion

Incorporating HUAHUA CNC technology into furniture production lines offers a cost-effective solution for manufacturers seeking to improve operational efficiency. The combination of automation and precision not only reduces labor costs but also enhances the quality of the products. For manufacturers looking to upgrade their production systems, HUAHUA CNC provides comprehensive, intelligent solutions that align with the demands of modern furniture making.